36 stainless steel phase diagram

which sigma phase is found and often hasten the kinetics of the sigma phase transformation (Refs. 8, 17-20). Howev er, the exact role that these factors play in promoting sigma phase formation is still somewhat obscure. Studies have been conducted recently on the phase stability of Types 308 and 308CRE* stainless steel, both in the as- Austenitic stainless steels have been widely used in many engineering fields because of their high corrosion resistance and good mechanical properties.

by G Jacob · 2018 · Cited by 8 — Additive Manufacturing; Austenite; Cryogenic; Delong Diagram; Equivalent chromium content; Heat treatment; Martensite; Nickel Equivalent; Powder Bed Fusion; ...38 pages

Stainless steel phase diagram

by I Calliari · 2020 · Cited by 4 — phase precipitation in a 2510 Duplex Stainless Steel, ... The calculated diagram reported in Figure 1 represents the mole fraction of the ... phase diagrams. As a rule, percentages of two principal elements are shown on the horizontal axis of a figure, while temperature variation is shown on the vertical axis. However, the constitutional diagram of a pure ... broadly known as steel. Even in the highly alloyed stainless steels, it is the quite minor constituent austenitic stainless steels is to present 302 as a base. Figure 2 shows one such diagram. Dia-grams such as these treat alloys as an evolution-ary family tree and subtly mislead. Many alloys were pushed toward obsolescence because of advances in processing. For instance, 321 was developed as an alloy in which the detrimental

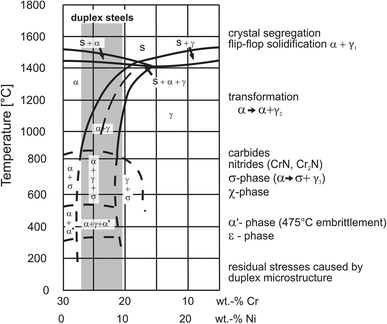

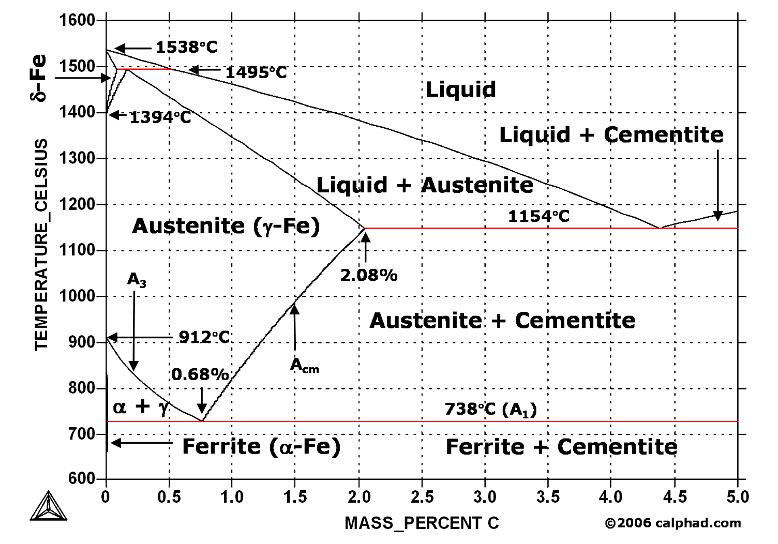

Stainless steel phase diagram. mass fraction of each phase is 0.5, estimate: (a) The temperature of the alloy (b) The compositions of the two phases Solution (a) We are given that the mass fractions of α and liquid phases are both 0.5 for a 30 wt% Sn-70 wt% Pb alloy and asked to estimate the temperature of the alloy. Using the appropriate phase diagram, Figure 9.8, by trial The phase diagram illustrates the domains in which particular phases or combinations of phases are stable, and contains information about their equilibrium compositions. Equilibrium phase fractions can also be estimated from a knowledge of the carbon concentration of the steel and an application of the lever rule. (a) Duplex stainless steel, IC378, hot rolled in the direction indicated. The darker etching phase is ferrite and the remainder is austenite (b) Duplex stainless steel IC381 (dark phase is ferrite). (c) Duplex stainless steel IC381 (dark phase is ferrite). (d) Superduplex stainless steel A219 after heat treatment at 1150°C for 2.5 h. Steel group: Austenitic stainless steels Note: TTT diagram for several commercial austenitic stainless steels with different molybdenum and nitrogen contents. As chromium and molybdenum increase to very high levels in the most highly alloyed HPASS, intermetallic phases form at even shorter times.

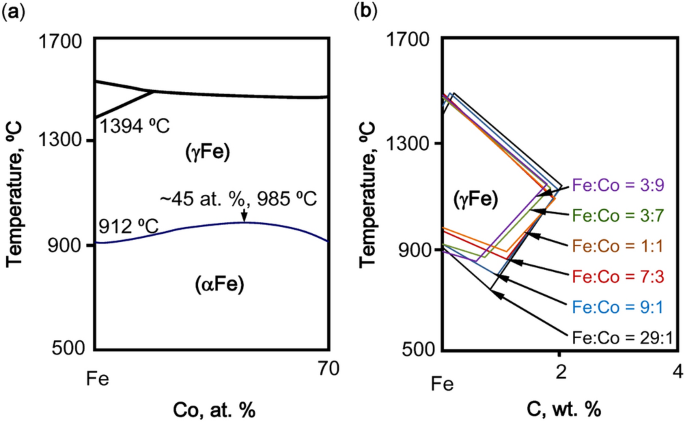

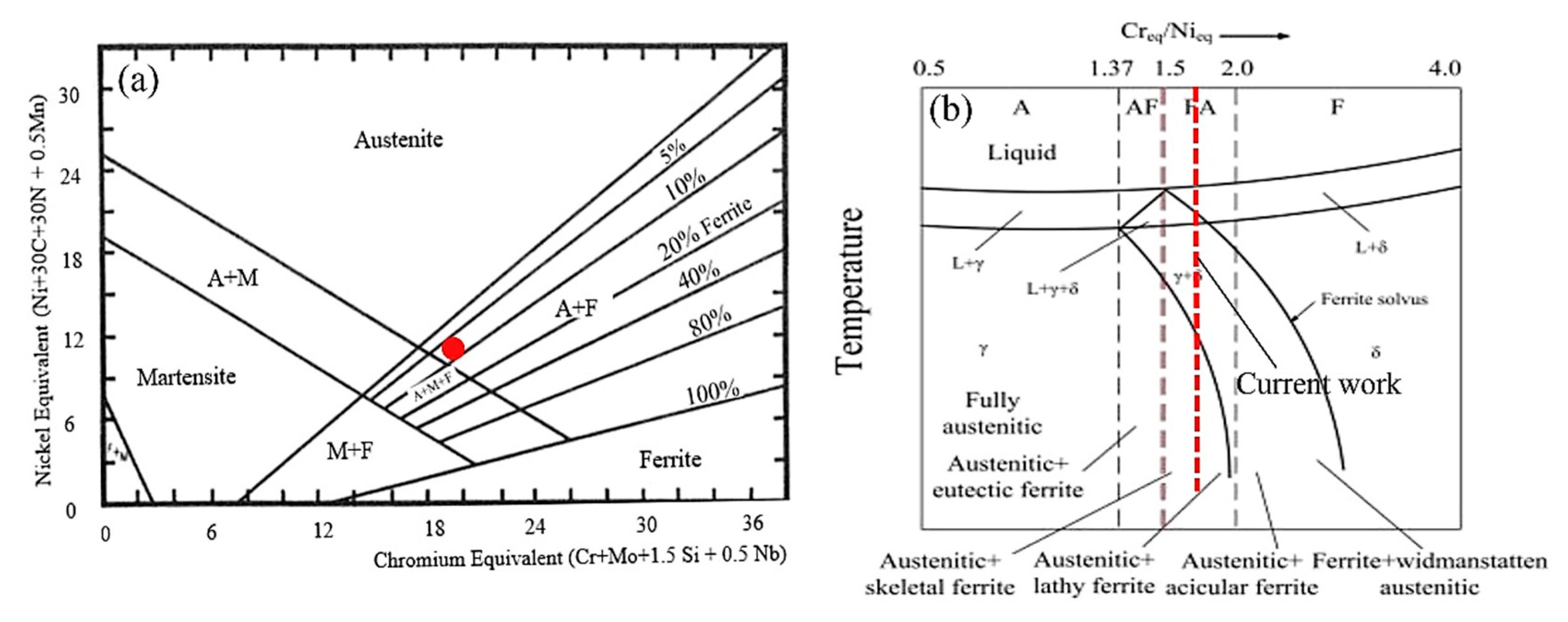

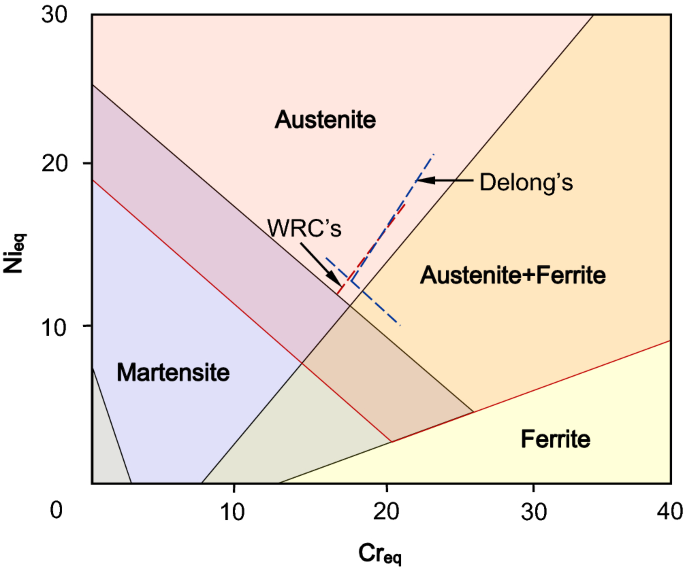

tures and properties. These diagrams have been very successful in predicting the amount of delta ferrite in stainless steel weld metal. This paper is concerned with the predictability of austenitic weld metal microstructure and properties over a larger compositional range. There are two main different types of phase transformations associated with In order to understand stainless steel, we need to know about the phase diagrams a little. And the base phase diagram in stainless steel is the iron-chromium binary phase diagram. In the phase diagram, you can understand that at specific temperature and chemical composition, we can predict the phases the alloy can contain. Fig 1. Equilibrium phase diagram of type 18-8 austenitic stainless steel with carbon as a variable. Although it is considered as an austenitic steel it is evident from the diagram that the austenite phase (γ) is not thermodynamically stable at room temperature. However, very few commercial materials are used in their equilibrium state. austenitic stainless steels is to present 302 as a base. Figure 2 shows one such diagram. Dia-grams such as these treat alloys as an evolution-ary family tree and subtly mislead. Many alloys were pushed toward obsolescence because of advances in processing. For instance, 321 was developed as an alloy in which the detrimental

phase diagrams. As a rule, percentages of two principal elements are shown on the horizontal axis of a figure, while temperature variation is shown on the vertical axis. However, the constitutional diagram of a pure ... broadly known as steel. Even in the highly alloyed stainless steels, it is the quite minor constituent by I Calliari · 2020 · Cited by 4 — phase precipitation in a 2510 Duplex Stainless Steel, ... The calculated diagram reported in Figure 1 represents the mole fraction of the ...

Composition Equivalents Of Stainless Steels Understood Via Gamma Stabilizing Efficiency Scientific Reports

Scielo Brasil Phase Separation And Development Of The Microstructure For Stainless Steel To Copper Alloy Weld Joints Using A Fiber Laser Phase Separation And Development Of The Microstructure For Stainless

Pdf Effect Of Intermetallic Phases On Corrosion Behavior And Mechanical Properties Of Duplex Stainless Steel And Super Duplex Stainless Steel Semantic Scholar

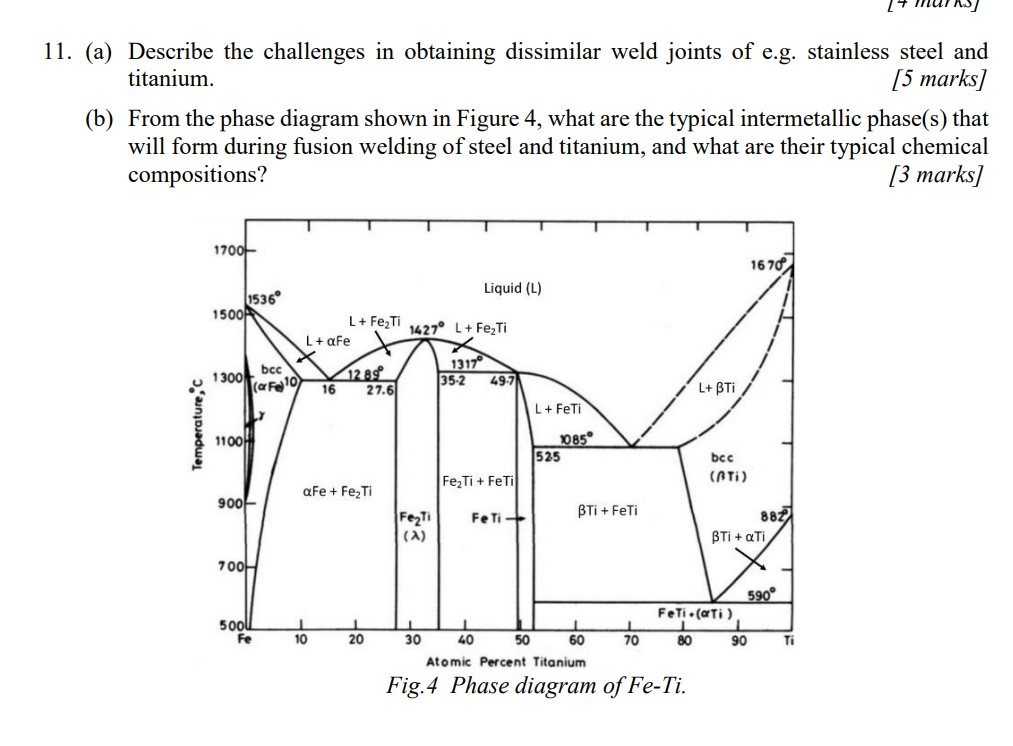

Applied Sciences Free Full Text Microstructure And Mechanical Properties Of Aisi 316l Produced By Directed Energy Deposition Based Additive Manufacturing A Review Html

Composition Equivalents Of Stainless Steels Understood Via Gamma Stabilizing Efficiency Scientific Reports

The Benefits To Using Duplex Stainless Steel By Yaang Com The Leading Manufacturer Of Super Duplex Stainless Steel Flanges Stainless Steel Flanges Stainless Steel Pipe Fittings Stainless Steel Pipe Etc

Figure 2 From Microstructure Evolution And Solidification Cracking In Austenitic Stainless Steel Welds Semantic Scholar

Pdf The Emphasis Of Phase Transformations And Alloying Constituents On Hot Cracking Susceptibility Of Type 304l And 316l Stainless Steel Welds Semantic Scholar

0 Response to "36 stainless steel phase diagram"

Post a Comment